Identify

Quickly identify and correct deficiencies

Assess

Perform hazard analysis and plan corrective measures

Control

Benchmark your performance and track your progress

Streamline your safety assessment and improve your risk performance

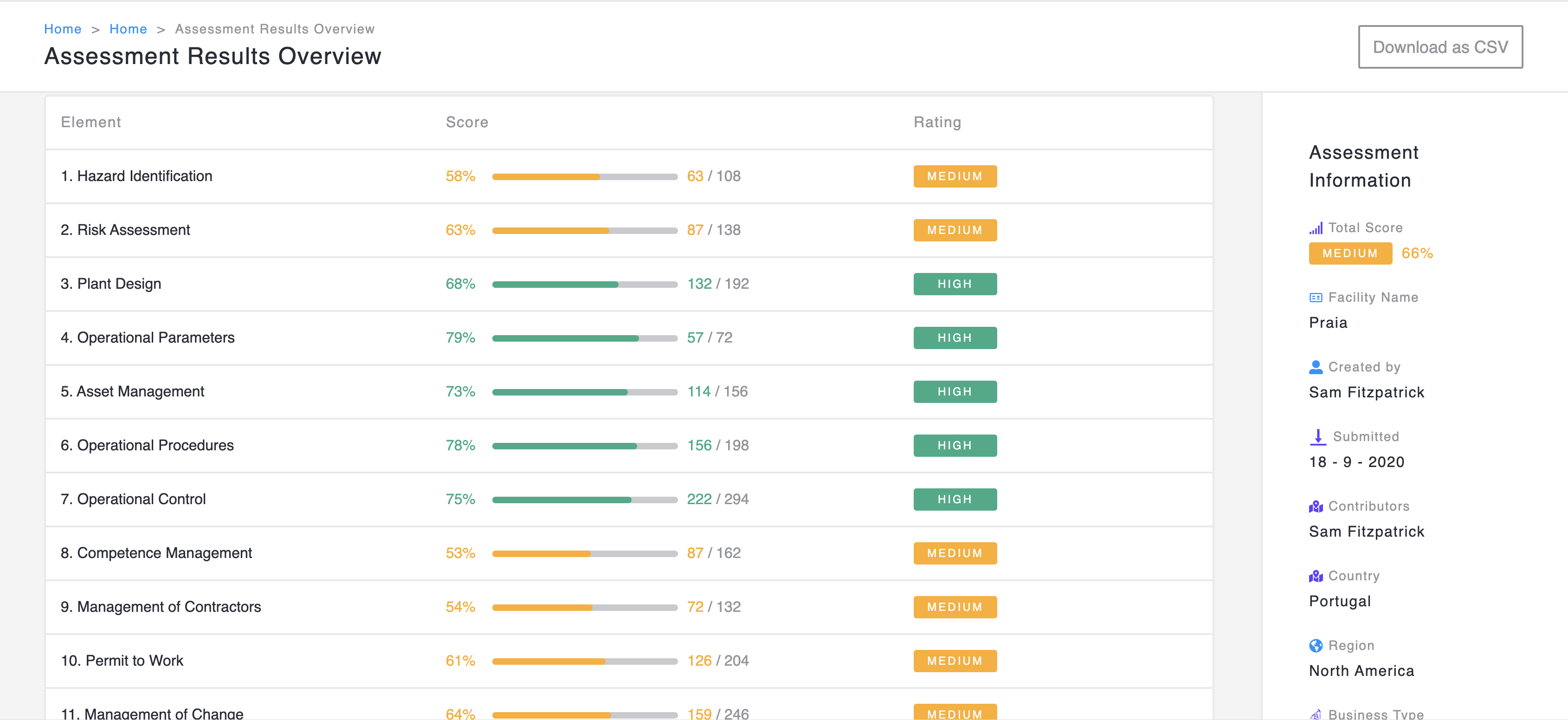

Get to know your strengths and weaknesses in controlling process risks.

A uniform way of seeing risk performance across business areas and facilities.

Track your performance and improvements in risk management over time.

Pinpoint areas which need improvement and common weaknesses across business areas.

Actively engage managers in achieving high standards of risk performance.

How it works

Assess your compliance against a world leading process safety management standard. Benchmark performance across multiple facilities. Become an expert in auditing your own control systems.

1

Identify a manager who will create the assessment.

2

Assesses control of risk against pre-determined focus points, by answering question sets developed by world expert in process safety.

3

Provide and record evidence against each criteria.

4

Reveal your performance score and identify gaps in your risk management.

5

View your improvement programme.

6

Managers and safety departments can view scores, gaps and planned improvements across all facilities.

7

Track progress against these benchmarks over time.

Why use the PSM

Even in well managed organisations, systems to control risk can deteriorate without warning or visibility to managers. With the PSM tool you can:

Easily demonstrate how you are managing risk.

Identify best practice within your business.

Set benchmarks for your safety compliance.

Major accidents with devastating consequences are happening all the time

The most common reasons why risk management systems fail are:

1.

Failure to appreciate hazard/risk by those directly involved in the activity.

2.

Familiarisation with activity – complacency.

3.

Deviation from the designed system/procedures.

4.

Tolerance of deviation by supervisors and managers.

5.

Willful or passive neglect of maintenance.

6.

Failure to detect and act on previous incidents.

7.

Lack of a shared and deep-rooted understanding of process safety risks and the measures needed to control those risks.

8.

Inability to learn from incidents – internal or external.

9.

Failures in Leadership and Corporate Governance.

10.

Belief in the infallibility of control systems.

11.

Poor or non-existent safety culture.

For a more detailed analysis download our process safety management whitepaper.

Thank you for downloading the whitepaper

Customer Testimonials

We wanted to understand our strengths and weaknesses in high hazard risk management in our refineries and other fuel storage and distribution businesses to identify where improvements were needed and where good practice was in place. The PSM audit protocol was perfect to gauge performance in different business areas and provide the findings in a clear and consistent way. It has helped us move forward along a clear path to improvement.

Joaquim Correia

Safety Engineer Oil & Gas

Galp Energia, Portugal

We operate across most of Europe providing essential power supplies from modern Gas Turbine stations, conventional fossil fuels and hydro-electric stations, gas storage assets and including the supporting networks and infra structure. As part of our PSM implementation program we used the PSM Audit protocol to gather evidence on where we had best practice and also where we also needed to improve. The discussion which took place at site in providing the evidence of compliance was especially enlightening and made sure we all thoroughly understood the concepts of process safety management.

Denis La Licata

Team Leader Process Safety

Uniper

We wanted to clearly understand how well our current manufacturing facilities meet good practice in process safety management before we embarked on a significant improvement programme. The gap analysis using the audit helped us to prioritise our implementation plan and to communicate those priorities clearly with our factory managers and our senior management team.

N Jagannadha Rao

Chief Manager – Corporate Quality and Safety

Asian Paints